Understanding Soda Coolers

Soda coolers, often found in convenience stores, restaurants, and homes, serve as essential appliances for keeping beverages chilled and refreshing. Whether used for commercial purposes or personal enjoyment, these units require a good understanding of their components and functionality to maintain their efficiency. Regular soda cooler repair and maintenance are vital to extending the lifespan of these machines.

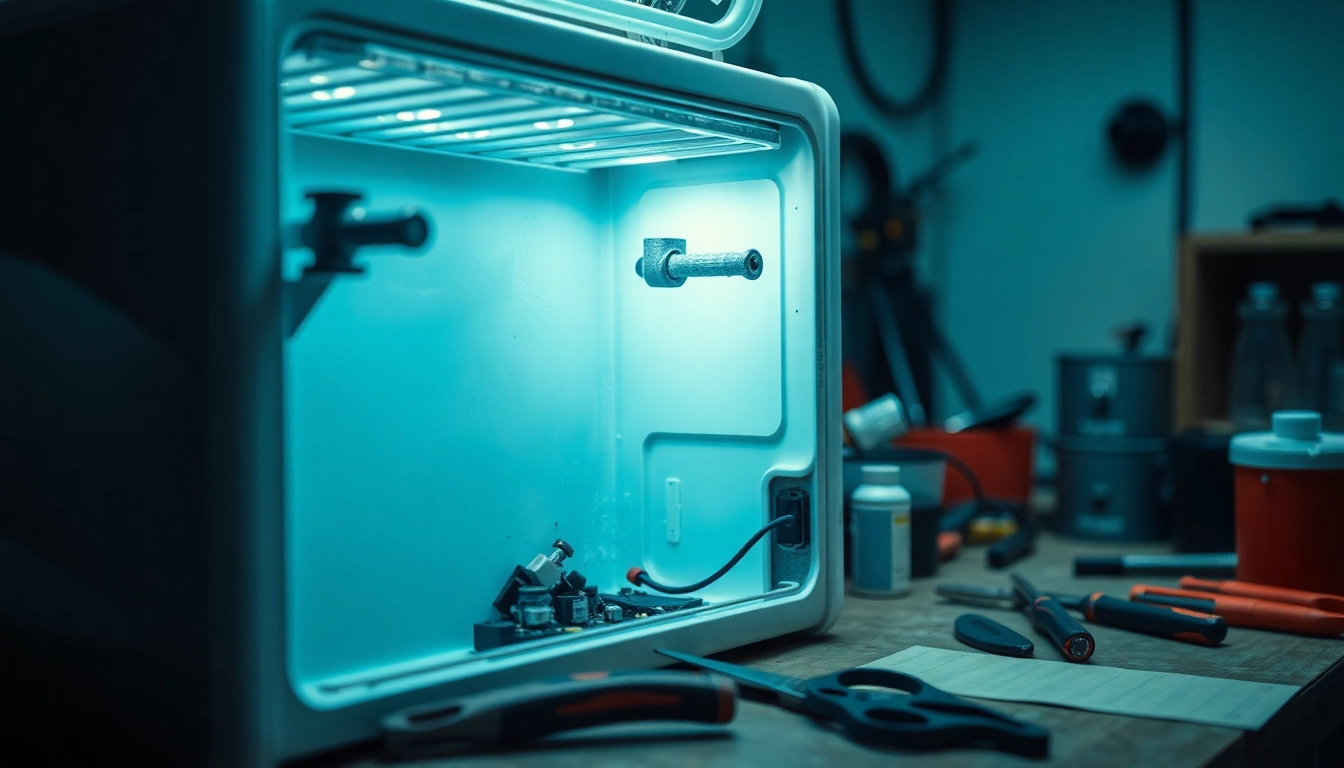

1. The Anatomy of a Soda Cooler

To troubleshoot and repair soda coolers effectively, it’s essential to be familiar with their anatomy. A typical soda cooler consists of the following components:

- Compressor: The heart of the cooling system, which compresses refrigerant and circulates it throughout the unit.

- Condenser: Responsible for dissipating heat from the refrigerant, allowing it to cool and condense.

- Evaporator: Absorbs heat from the interior of the cooler, providing the necessary cooling effect.

- Thermostat: Controls the temperature of the cooler by regulating the compressor’s operation.

- Fan: Helps circulate air for even cooling and assists in the condenser’s heat dissipation.

- Shelves and storage compartments: Where beverages are organized and displayed for easy access.

2. Common Issues in Soda Cooler Repair

Soda coolers are not immune to malfunctions. Some common issues include:

- Cooling Failure: This can occur due to a faulty compressor, a malfunctioning thermostat, or refrigerant leaks.

- Noise Problems: Unusual sounds can indicate issues with the compressor or the fan motor.

- Inefficient Performance: This could be due to dust buildup on coils, obstructed airflow, or worn-out seals.

- Electrical Issues: Malfunctioning components like fuses, wiring, or power switches can prevent the cooler from operating effectively.

3. Importance of Regular Maintenance

Regular maintenance of soda coolers is crucial for ensuring their longevity and efficient operation. Performing routine check-ups can help identify potential problems before they escalate into costly repairs.

Tasks like cleaning condenser coils, checking for refrigerant leaks, inspecting door seals, and ensuring proper airflow can significantly enhance a cooler’s performance and energy efficiency.

Diagnosing Problems

1. Identifying Signs of Malfunction

Recognizing the early signs of a malfunction can save time and money. Look out for:

- Temperature Fluctuations: Inconsistent temperatures might indicate thermostat issues.

- Excessive Noise: This may signal a failing compressor or loose components.

- Frost Build-up: Unexpected frost in the evaporator can suggest airflow issues or refrigerant problems.

- Water Leaks: Puddles around the unit can indicate blockages in the drain line or a failing evaporator.

2. Tools Needed for Diagnosis

To diagnose issues effectively, having the right tools is essential. Recommended tools include:

- Multimeter (for testing electrical components)

- Thermometer (for measuring internal temperatures)

- Refrigerant gauges (for checking refrigerant levels)

- Screwdrivers and wrenches (to access components)

- Vacuum cleaner or brushes (for cleaning)

3. Safety Precautions While Repairing

Safety should be a top priority when repairing soda coolers. Follow these precautions:

- Always unplug the unit before performing any repairs.

- Use insulated tools when working with electrical components.

- Wear gloves and goggles to protect against refrigerants and sharp edges.

- Ensure proper ventilation when working with chemicals or cleaning agents.

Repair Techniques

1. Quick Fixes for Common Problems

Here are some quick fixes for frequent soda cooler issues:

- Cooling Failure: Check the power supply, ensure the thermostat is set correctly, and inspect door seals for leaks.

- Noisy Operation: Tighten loose screws and examine fan blades for obstructions.

- Frost Build-up: Defrost the unit and ensure the evaporator fan is functioning correctly.

2. Step-by-step Repair Guide

For a more involved repair, follow these steps:

- Turn Off Power: Unplug the soda cooler to ensure safety.

- Inspect Components: Check the compressor, condenser, and evaporator for visible signs of damage or wear.

- Test Electrical Connections: Use a multimeter to check for continuity in the wiring and connections.

- Check the Refrigerant: Using refrigerant gauges, assess the refrigerant level and look for leaks.

- Replace Defective Parts: If a component is faulty, replace it with a compatible part.

- Reassemble and Test: Reassemble the cooler, restore power, and check for proper operation.

3. When to Call a Professional for Soda Cooler Repair

While DIY repairs can be effective, certain situations warrant professional assistance, including:

- Sealed system failures, such as compressor or refrigerant leaks.

- Complex electrical issues that are beyond basic troubleshooting.

- Repeated breakdowns despite regular maintenance and repairs.

Preventing Future Issues

1. Best Practices for Maintenance

Implementing best practices in maintenance can prevent future issues:

- Clean condenser coils biannually to enhance efficiency.

- Change air filters regularly if applicable.

- Conduct regular temperature checks to ensure optimal performance.

- Inspect and replace worn seals to prevent air leaks.

2. Choosing the Right Environment for Your Cooler

The placement and environment of your soda cooler can impact its performance significantly. Consider the following:

- Avoid Direct Sunlight: Keep the cooler away from heat sources to prevent overheating.

- Ensure Proper Ventilation: Allow space around the unit for air circulation.

- Maintain Optimal Ambient Temperature: Ideal conditions help enhance efficiency and prevent strain on components.

3. Regular Check-ups: Keeping Your Cooler in Peak Condition

Implementing a regular check-up schedule can help keep your soda cooler in excellent working condition:

- Every three months, conduct a basic inspection for dust buildup and clean as necessary.

- Annually, consider a professional servicing to ensure all components are functioning correctly.

- Maintain a log of repairs and maintenance performed to keep track of any recurring issues.

Finding Professional Help

1. Evaluating Repair Services

When seeking professional repair services, consider the following criteria:

- Experience: Look for technicians with a strong track record in soda cooler repair.

- Certifications: Ensure they are certified and familiar with your specific model.

- Customer Reviews: Read reviews and testimonials to gauge their reliability and service quality.

2. Average Costs for Soda Cooler Repairs

The cost of repair services can vary based on the extent of the damage and labor charges. On average, expect to pay:

- Minor repairs: $75 – $150

- Moderate repairs including parts replacement: $150 – $500

- Major repairs like compressor replacement: $500 – $1500

3. Reviews and Recommendations for Repair Technicians

Personal recommendations from friends or online forums can be valuable when searching for professional help. Platforms like Yelp or Angie’s List often provide user-generated reviews that can guide your choice. Look for technicians that specialize in commercial appliances and have experience with the specific brand of your cooler.